- SKF Alignment Tool

- Condition Monitoring

-

Vehicles Steering & Suspension

Systems - SKF Bearings

-

Fittings & Accessories for Lubrication

Systems - SKF TOOLS

- Manual Grease Guns

- SKF Refill Pumps

a) SKF SHAFT ALIGNMENT TOOL

|

SHAFT ALIGNMENT TOOL MODELS

•Shaft alignment tool TKSA 11 •Shaft Alignment Tool TKSA 31 •Shaft alignment tool TKSA 41 •Shaft alignment tool TKSA 51 •Shaft alignment tool TKSA 71 |

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

b) BELT ALIGNMENT TOOLS

|

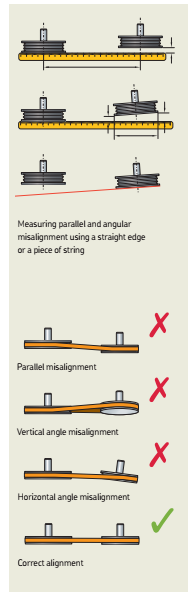

Traditional belt alignment methods

These methods are usually visual in combination with a straight edge and/or length of string. Although quick to perform, they are often inaccurate.

Laser belt alignment methods

Using a laser belt alignment tool is quicker and more accurate than traditional methods. Belt alignment tools can either align the pulley faces or the pulley grooves.

Accurate pulley and belt alignment can help you: •Increase bearing life •Increase machinery uptime, efficiency and productivity •Reduce wear on pulleys and belts •Reduce friction and thereby energy consumption •Reduce noise and vibration •Reduce costs of replacing components and machinery downtime

|

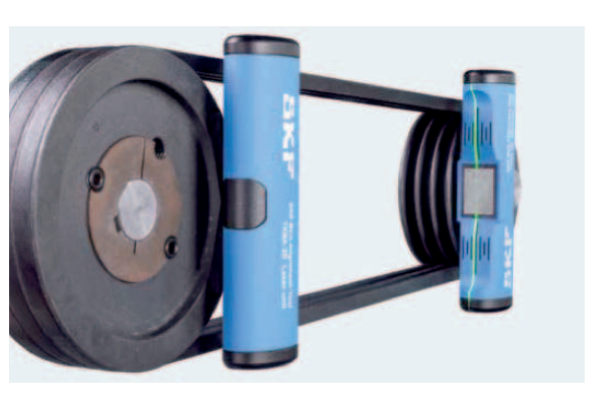

Versatile tools for pulley and sprocket alignment TKBA 10 and TKBA 20The SKF TKBA 10 and TKBA 20 allow pulleys and sprockets to be aligned on the side face. The unit magnetically attaches to the inside or outside face of almost any belt pulley or chain sprocket and has no small parts or targets that can get lost. A laser line is projected from the transmitter unit to the reflector unit mounted on the opposite pulley. A reference line on the reflector unit directly indicates the offset and vertical angle misalignment. The reflected laser line shown on the transmitter unit shows the horizontal angle misalignment of all three. • Powerful magnets allow fast and easy attachment • Facilitates simultaneous adjustment of tension and alignment • Can be used on almost all machines using V belts, banded belts, ribbed belts and most other belts as well as chain sprockets • SKF TKBA 10 utilises a red laser and can be used for distances up to 3 m (10 ft) • SKF TKBA 20 utilises a highly visible green laser and can be used for distances up to 6 m (20 ft). It can even be used outdoors in sunny conditions • Sturdy aluminium housings help ensure assembly stability and accuracy during the alignment process |

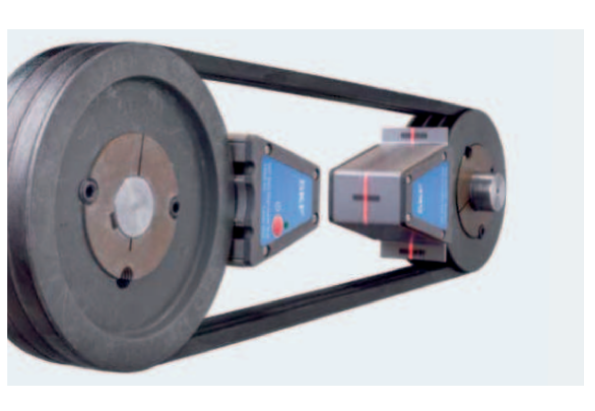

Highly accurate tool for V-belt pulley alignment TKBA 40The SKF TKBA 40 aligns V-belt pulleys in the grooves. V–guides and powerful magnets allow the TKBA 40 to be fitted in the grooves of the pulley. With only two components, a laser–emitting unit and a receiver unit, the belt alignment tool is easy and fast to attach. The three–dimensional target area on the receiver unit allows the easy detection of misalignment as well as its nature; whether it is horizontal, vertical, parallel or a combination of all three. • Powerful magnets allow fast and easy attachment • Three-dimensional target area simplifies the alignment process • Facilitates simultaneous adjustment of tension and alignment • V-guides facilitate the alignment of a wide range of V-belt pulleys • Aligns grooves of a V-belt pulley rather than its face, allowing optimum alignment of pulleys of unequal width or with dissimilar faces • A maximum operating distance of 6 m (20 ft) accommodates many applications • Special side adaptor allowing alignment of multi-ribbed and timing belt pulleys as well as sprockets is available as accessory |

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

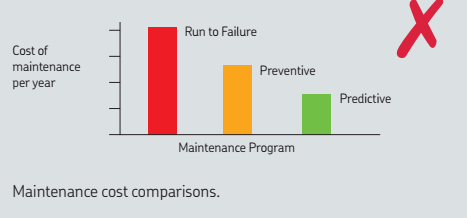

BASIC CONDITION MONITORING

To help ensure long bearing service life, it is important to determine the condition of machinery and bearings while in operation. Good predictive maintenance will help reduce machine downtime and decrease overall maintenance costs. To help you achieve the maximum service life from your bearings, SKF has developed a wide range of instruments for analysing the critical environmental conditions which have an impact on bearing and machine performance.

MAINTENANCE CONCEPTS

Run to failure Run to failure occurs when repair action is not taken until a problem results in machine failure. Run to failure problems often cause costly secondary damage along with unplanned downtime and maintenance costs. |

|

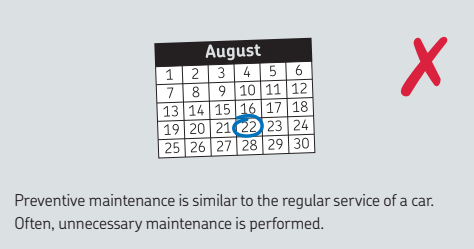

Preventive maintenance Preventive maintenance implies that a machine, or parts of a machine, are overhauled on a regular basis regardless of the condition of the parts. While preferable to run to failure maintenance, preventive maintenance is costly because of excessive downtime from unnecessary overhauls and the cost of replacing good parts along with worn parts |

|

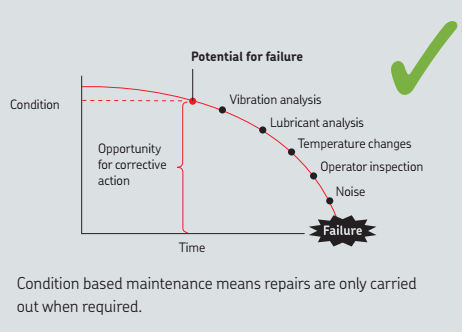

Predictive maintenance Condition monitoring/predictive maintenance is the process of determining the condition of machinery while in operation. This enables the repair of problem components prior to failure. Condition monitoring not only helps plant personnel reduce the possibility of catastrophic failure, but also allows them to order parts in advance, schedule manpower, and plan other repairs during the downtime. With condition monitoring, machinery analysis takes two overlapping forms: predictive and diagnostic. |

|

SKF basic condition monitoring tools can be used to check a number of properties:

Temperature Since the dawn of the industrial age, operators and technicians know that abnormal temperatures often indicate that something is wrong with the machine. Thermometers can help find and then measure these hotspots, allowing further analysis to be conducted. |

|

Speed Machines are usually designed to run at a given speed. If the speed is too slow or too fast, then the overall process can be compromised. Using a hand-held tachometer enables a quick and easy assessment of the machine’s running speed. |

|

Visual Visual inspection of a machine’s condition can sometimes be difficult when it’s running or when there is a need to inspect the machine internally. A stroboscope can be used to visually freeze the motion of a machine to allow such things as fan blades, couplings and belt drives to be inspected while running. To inspect the internal parts of a machine often requires disassembly. By using an endoscope, it is possible to access the area of interest with minimal disassembly, saving time and money. |

|

Sound Abnormal sounds from machines often indicate that something is wrong. A stethoscope can be used to help pinpoint the source of the sound and can aid the technician in identifying the problem. Leaks in compressed air systems are costly, not only in energy costs but also due to extra costs in air compressor maintenance. Ultrasonic leak detectors can help detect leaks efficiently, allowing the necessary repairs to be made. Excessive noise can cause worker fatigue, increased accidents and loss of hearing. A sound pressure meter can measure the sound level, allowing corrective measures to be made. |

|

Electrical discharge currents Electrical discharges are a result of motor shaft voltages discharging to earth through the bearing, causing electrical erosion, lubricant degradation and ultimately bearing failure. An electrical discharge detector can help detect the presence of electrical discharge currents, allowing remedial action to be taken. |

|

Vibration Abnormal vibrations are often the first indication of a potential machine failure. These vibrations can be caused by such conditions as unbalance, misalignment, looseness of parts, rolling element bearing and gear damage. Vibration analysis instruments and systems, can help detect many serious problems at an early stage, allowing remedial work to be undertaken in a timely manner |

|

Lubricant condition To maintain the optimum condition of rolling element bearings, it is essential that the lubricant is in good condition. Checking the oil or grease condition at regular intervals can reduce downtime and greatly prolong the life of rolling element bearings. |

|

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

a) TIH SERIES HEATING TOOLS

|

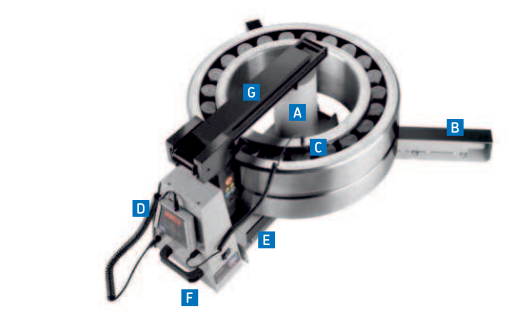

TIH series Features and benefits The comprehensive SKF induction heater range can be used for efficiently heating bearings and workpieces, both large and small. Their innovative design offers significant advantages to both owners and operators:Advanced power electronics, with accurate electric current control, help control the temperature rate increase Two step power setting option (50% / 100%), enables small bearings to be heated safely and at a lower power consumption For heating components other than bearings, all heaters are equipped with a heating time mode and for large components, optimized TIH MB heaters for solid workpieces are available Thermal overheating protection reduces the risk of damage to the induction coil and electronics, enhancing reliability and safety Automatic demagnetisation reduces the risk of ferrous debris contamination after heating Available in different voltage variants, to suit most operating voltages worldwide Supplied with heat-resistant gloves for improved operator safety |

A Induction coil located outside the heater’s housing enables a shorter heating time and lower energy consumption B Foldable bearing support arms allow larger diameter bearings to be heated, and reduce the risk of the bearing toppling during heating C Magnetic temperature probe, combined with a temperature mode preset at 110 °C (230 °F), helps prevent bearing overheating D Unique SKF remote control, with operating display and control panel, makes the heater easy and safe to use E Internal yoke storage, for smaller yoke(s), reduces the risk of yoke damage or loss F Integrated carrying handles allow for easy movement of the heater in the workshop G Sliding or swivel arm allows for easy and quick bearing replacement, reducing operator fatigue (not for TIH 030m) |

TIH series Models

|  |  |

| Small induction heater with a 40 kg bearing heating capacity TIH 030m - Compact lightweight design; just 21 kg (46 lb), facilitating portability - Capable of heating a 28 kg (62 lb) bearing in just 20 minutes - Supplied standard with three yokes, allowing bearings with a bore diameter from 20 mm (0.8 in.) up to a maximum weight of 40 kg (90 lb) to be heated | Medium induction heater with a 120 kg bearing heating capacity TIH 100m - Capable of heating a 97 kg (213 lb) bearing in less than 20 minutes - Supplied standard with three yokes, allowing bearings with a bore diameter from 20 mm (0.8 in.) up to a maximum weight of 120 kg (264 lb) to be heated - Swivel arm for large size yok | Large induction heater with a 300 kg bearing heating capacity TIH 220m - Capable of heating a 220 kg (480 lb) bearing in just 20 minutes - Supplied standard with two yokes, allowing bearings with a bore diameter from 60 mm (2.3 in.) up to a maximum weight of 300 kg (660 lb) to be heated - Sliding arm for large size yoke |

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

b) SKF TKTL Infrared thermometers

TKTL Series | SKF offers a wide range of portable, lightweight and easy-to-use infrared thermometers for thermal inspections. These portable tools help you to detect temperature differences in technical and non-technical applications, this in order to perceive information on abnormalities in operating. SKF Infrared thermometers are fitted with multiple lasers which helps you to easy and more accurate target the object. The TKTL 21, 31 and 40 also offer you the option of measuring temperatures via a temperature probe. The TKTL 40 offers you the possibility of data logging and allows pictures and videos with all measurement information to be taken |

| TKTL 11 Basic infrared thermometer - LCD colour display - 8 laser targeting - Fixed emissivity - High accuracy - Fast response time - DS ratio of 16:1 | TKTL 21 Advanced infrared thermometer - LCD colour display - 8 laser targeting - Type-K thermocouple probe - Adjustable emissivity - High accuracy - Fast response time - DS ratio of 30:1 | TKTL 31 High performance infrared thermometer - LCD monochrome display, backlit - Dual laser targeting - Type-K thermocouple probe - Adjustable emissivity - High accuracy - Fast response time - DS ratio of 75:1 | TKTL 40 Dual laser infrared and contact video thermometer - 2.2” TFT LCD display - 640 x 480 pixels digital camera - Internal memory expandable to 8 GB (Micro SD card) - Image (JPEG) and video (MP4) - Humidity and air temperature - Dual laser targeting - Type-K thermocouple probe - Adjustable emissivity - High accuracy - Fast response time - Dewpoint temperature and wet bulb temperature |

c) TACHOMETERS TKRT SERIES

Tachometers TKRT Series | SKF offers its TKRT range of tachometers, which use laser or contact measurement to determine the rotational and linear speed of rotating equipment. Each handheld device is compact in design, and offers fast, accurate measurement. The laser sensor allows measurements to be made at a safe distance from rotating machinery. Each device is supplied with contact adaptors and uses standard or rechargeable batteries. Output information is clearly displayed on a large, easy-to-read screen. Measurement modes include: rotational speed, total revolutions, frequency, surface speed and length – in both metric and imperial units. The breadth of measurement modes, and wide speed range, make the tachometers suitable for use in a variety of applications |

| TKRT 10 Digital tachometer - Laser/contact measuring system - Wide speed measurement range - Multiple measurement modes - Large, back-lit LCD display - Angular range of ±45° for easy measuring - Up to 10 readings stored for reference - Includes basic set of contact adaptors | TKRT 21 Multi-functional digital tachometer - Laser/contact measuring system - Wide speed measurement range - Multiple measurement modes - Large LCD display - Includes basic set of contact adaptors - Uses standard or rechargeable batteries | TKRT 31 Advanced digital tachometer - Large colour-backlit TFT display - Measures linear and rotational speed, and distances - Includes full set of contact adaptors - Large angular range simplifies measurement, where straight line access is difficult |

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

d) STROBOSCOPES

High-performance, hand-held stroboscopes for visual inspection

Stroboscopes

SKF offers a wide range of portable TKRS stroboscopes for visual inspection of running machines in challenging industrial environments. These portable tools provide early detection of abnormalities to help schedule maintenance tasks and reduce additional loads on rotating equipment in order to reach planned performance levels. Designed for ease of use, the four TKRS models offer from 3 to 118 ultra-bright LEDs. Each stroboscope features a large screen and multifunctional selector switch to help you quickly navigate to the correct menu. Brightness and performance levels are adjustable.

| TKRS 11 - Quick speed selection with rotary button - Black and white LCD display - Three ultra-bright LEDs | TKRS 21 - High luminescence with seven - ultra-bright LEDs - Multi-line backlit TFT | TKRS 31 - Built-in laser tachometer with flash synchronization - Pro-mode with additional features like slow motion phase shift - Trigger input and output with signal modification |

|  |  |

| TKRS 41 - Extreme luminescence with 118 ultra-bright LEDs - Portable operation with built-in rechargeable battery - Continuous operation for long term inspection with power adapter - Flash synchronization from laser tachometer or trigger input |

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

e) Endoscopes TKES 10 series

Fast and easy inspection with video function | SKF Endoscopes are first line inspection tools that can be used for internal inspection of machinery. They help minimise the need to disassemble machinery for inspection, saving time and money. The compact display unit, with 3.5” backlit screen, allows images and video to be saved and recalled, or to be downloaded and shared with others. Three different models cater to most needs and are equipped with powerful variable LED lighting allowing inspections in dark locations. • High resolution miniature camera, with up to 2× digital zoom, gives a clear and sharp full screen image • Available with a 1 metre (3.3 ft) insertion tube in three different variants; flexible, semi-rigid or with an articulating tip • Small tip diameter of 5,8 mm (0.23 in.), with a wide field of view, allows easy access to most applications • Supplied with a side view adapter allowing inspection of applications such as pipe walls • Powerful magnets, and a tripod mount on the back of the display unit, allow the display unit to be used “hands free” • Up to 50 000 photos or 120 minutes of video can be stored on the SD memory card supplied • Longer flexible and semi-rigid insertion tubes are available as accessories • Supplied in a sturdy carrying case complete with all necessary cables, universal mains charger and cleaning kit |

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

Condition monitoring products

SKF Steering & Suspension systems covering most the vehicle in the market.

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

Master Interchange – For automotive, heavy truck, and agricultural bearings

Includes the following types:

ball, cylindrical, needle, tapered, special bearings and hub assemblies

For more details, please visit: skf.com | mapro.skf.com | skf.com/lubrication

| – Tapered sleeve fittings according to DIN 3854/DIN 3862 – High-pressure cutting sleeve unions according to ISO 8334-1 – Double-edged cutting sleeve union (DECS) – Soft-seal cutting sleeve union (SSCS) – Adapters, plugs and washers – Quick connectors – Single-seal quick connectors – Triple-seal quick connectors | – Manifolds – Tubes and hoses – Fixing material – Couplings – Valves – Pressure gauges – Reservoirs – Lubricating nipples – Filters – Brushes |

Pipe cutter | Description This manual pipe cutter is particularly suitable for pipes made of copper, brass, light metal and hard plastic, as well as for steel and stainless-steel pipes with outside diameters from 3 to 35mm and a maximum cutting depth of 2.5mm Features and benefits – Optimal hold of the tube when cutting with two guide rollers – Combines accuracy with ease of use – Optimal size, light weight Applications – Metal and plastic forming machinery – Construction machinery – Agriculture, automation – Printing |

Claw groove tool | Description The manual claw groove tool is suitable for hardened copper, brass, steel and stainless steel tubes with diameters of 4, 6, 8 and 10mm. It allows the creation of claw grooves on metal pipes that are needed for use with SKF quick connectors Features and benefits – One compact tool for both cutting and grooving – Combines accuracy with ease of use – Optimal size, light weight Applications – Metal and plastic forming machinery – Construction machinery – Agriculture, automation – Printing |

Tube Bender Applications – Metal and plastic forming machinery – Construction machinery – Textile machinery – Agriculture – Automation – Printing | Description The easy-to-use manual tube bender is designed for pipe diameters of 6, 8 and 10mm and has a bending radius range from 1-180° with a visible, marked scale featuring 15° steps. The bender is suitable for use with hardened copper, steel and stainless steel tubes. Features and benefits – Designed for bending hardened copper, steel and stainless steel – Provides measurements in inches and millimeters – Combines accuracy with ease of use – Optimal size, light weight – Includes oil-absorbing shoe |

Tube bending fix Applications – Metal and plastic forming machinery – Construction machinery – Textile machinery – Agriculture – Automation – Printing | Description Designed for installation on a workbench, the manual tube bending fix is suitable for hardened copper, steel and stainless steel tubes with diameters of 4, 6, 8 and 10mm. Its bending radius range is 1-180°. Features and benefits – One compact tool for workbench assembly with exchangeable bending disks – Combines accuracy with ease of use – Optimal size, light weight |

Tube cutter | Description This manual tube cutter is particularly suitable for tubes and hoses made of plastic and rubber, including tubes with thin metal layers. It cuts tubes with outside diameters up to 12.5 mm Features and benefits – Combines accuracy with ease of use – Highly resistant against stress and flexural vibrations – Small size, light weight Applications – Metal and plastic forming machinery – Construction machinery – General industry – Agriculture – Printing |

Grease pump set for pressure and function check Applications – Metal and plastic forming machinery – Construction machinery – General industry – Agriculture – Printing | Description This manual grease pump set for pressure and function check is a perfect tool for lubrication system installation, maintenance or troubleshooting existing systems. Its integrated pressure gauge, hose and fitting enable accurate system function check and help to identify system leaks as well as system blockages. The set includes two different connection options: a hydraulic coupler for grease nipple, and a fitting for connection of tube ∅6 mm. Features and benefits – Combines accuracy with ease of use – Set contains a wide range of fittings – Robust and reliable tool – Small size, light weight |

Drum plug wrench Features and benefits – Suitable for common cap types – both plastic and metal – Non-sparking, non-corrosive aluminum construction – Saves time and effort when loosening and tightening plugs and caps – Fits large and small caps – Cost-effective solution – Simple to use | Description The drum plug wrench was developed to simplify the opening and closing of caps and plugs on fluid drums. The model 5841 wrench eliminates the need for cumbersome makeshift tools, such as screwdrivers and hammers. Constructed of safe, non-sparking cast aluminum, the drum plug wrench features a comfortable, textured grip. This cost-effective wrench is suitable for agriculture, construction, industrial, fleet maintenance and vehicle service applications – anywhere that fluid drums are used. It is compatible with standard metal and plastic caps or plugs on 60 l (16 gal) and 200 l (55 gal) drums Applications – Caps or plugs on 60 l (16 gal) and 200 l (55 gal) drums |

Socket wrench insert for elbows Applications – Metal and plastic forming machinery – Construction machinery – General industry – Agriculture – Printing | Description This socket wrench insert for elbow fitting mounting allows quick and clean system installation work, especially in machines or in facilities where lubrication lines have to run around many corners and barriers. Features and benefits – Combines accuracy with ease of use – Highly resistant against stress and flexural vibrations – Small size, light weight |

Mounting stud for hose couplings Applications – Hose mounting for nominal diameter 6 mm | Description The mounting stud is an important tool for the self-assembly of threaded joints of high-pressure hoses. With the aid of the stud, it is possible to mount the threaded sleeve in the correct position in the high-pressure hose. This is important because incorrectly mounted sleeves can cause the hose to burst or couplings not to seal. Features and benefits – Simple mounting without complex measuring with caliper – Avoids malfunctions in the central lubrication system due to blocked or burst hose lines – Avoids errors during hose assembly |

Manual grease filler guns  Applications – General mechanic and plant engineering – Agriculture, construction, automotive, trucking – Heavy equipment – Wind energy – General industry | Description The manual cartridge grease gun is ideal for agricultural, industrial and construction industries and for private use. It can be utilized to lubricate directly or as filler pump for automatic lubrication systems. The tool is designed for rough treatment on the job with a cast iron pump head, precision fit plunger and extra heavy follower spring. Features and benefits – For use with cartridges and bulk grease – Knurled body for firm and safe grip – High-output setting delivers twice the grease per stroke – High or low pressure for light- or heavy-duty greasing action – Extension swivels 360° for hard-to-reach fittings – Plated barrel, head and handle |

| PowerLuber Model 1260/ 1880 /1890  Applications – General mechanic and plant engineering – Agriculture, construction, automotive, trucking – Heavy equipment – Wind energy | Description PoweLuber Li-ion grease gun family is designed to make quick work of lubrication tasks. It contains the rugged simplicity of the 12V, single-speed model, the speed and versatility of the durable 20V, high ratio, two speed design and the advanced technology of the 20V with LCD. Features and benefits – Flex hose that comes with anti-kink spring guards on each end and is the ideal size for most lubrication tasks – Integrated vent valve purges trapped air to help assure easy prime – The filler nipple facilitates a quick, clean refill for those who prefer to bulk fill their barrel – Lithium-ion technology is powerful and efficient, delivering an even flow of energy – LCD display version shows battery charge and grease output in both grams and ounces |